Epoxy is really a type of resin which is created by mixing two parts collectively - a resin in addition to a hardener. When both of these parts are mixed, a chemical reaction happens, causing a powerful, strong materials which might be used for a number of apps. Epoxy is known for its exceptional adhesion, chemical resistance, and mechanical Qualities, rendering it a well known choice for an array of industries, which include design, automotive, aerospace, and maritime.

Epoxy is offered in a number of varieties, such as liquid, paste, and reliable, and can be used as an adhesive, coating, or filler. It can be applied to a wide array of surfaces, which include steel, wood, concrete, and plastic, making it a versatile substance for many different tasks. Epoxy is additionally readily available in a variety of hues and finishes, rendering it very easy to customize to suit the precise requires of the task.

Epoxy is usually applied in combination with other materials, for instance fiberglass or carbon fiber, to develop composite products which might be lightweight and strong. It will also be used like a protecting coating for surfaces which can be exposed to severe environments, which include chemical spills or extreme temperatures. Overall, epoxy is a flexible and sturdy content that has an array of apps throughout many various industries.

How Epoxy is Utilised

Epoxy is Employed in an array of purposes, from industrial to inventive. In the development sector, epoxy is often used as an adhesive for bonding materials jointly, including metallic to steel or metal to concrete. It is additionally used for a coating for floors and walls to supply safety against chemicals, abrasion, and moisture. In the automotive market, epoxy is used for bonding overall body panels and restoring destroyed parts. It is also utilised to be a protective coating for undercarriages as well as other metallic components to forestall corrosion.

During the maritime market, epoxy is employed for repairing fiberglass boats and generating personalized parts. It is usually utilized being a protective coating for hulls and decks to stop water intrusion and hurt from maritime organisms. During the aerospace business, epoxy is utilized for bonding composite resources alongside one another to create lightweight and strong structures. Additionally it is utilised for a protecting coating for plane parts to offer resistance versus Extraordinary temperatures and severe environments.

During the art globe, epoxy is utilized for producing sculptures, jewelry, along with other decorative products. It can be blended with pigments and various products to develop one of a kind layouts and finishes. Over-all, epoxy is a flexible materials that may be Employed in a wide array of programs, from industrial to artistic.

Great things about Employing Epoxy

There are several Advantages to using epoxy in many apps. Among the main great things about epoxy is its excellent adhesion Houses. When appropriately applied, epoxy varieties a powerful bond While using the substrate, making a durable and very long-lasting link. This makes it an excellent choice for apps where sturdy adhesion is required, for example in design and automotive industries.

Yet another good thing about making use of epoxy is its chemical resistance. Epoxy is very resistant to an array of substances, such as acids, solvents, and oils. This causes it to be a super choice for programs wherever publicity to harsh chemical substances is prevalent, such as in industrial settings or marine environments.

Epoxy also provides fantastic mechanical Houses, like substantial strength and toughness. This makes it a great choice for apps wherever longevity and impact resistance are important, like inside the aerospace industry or for making customized components inside the marine business.

As well as its physical Qualities, epoxy also offers aesthetic Advantages. It is offered in a variety of shades and finishes, which makes it simple to customize to suit the precise demands of a venture. This makes it a super option for programs exactly where appearance is crucial, for instance while in the art globe or for attractive coatings in household or business options.

General, epoxy offers a wide array of Rewards that make it a really perfect choice for many alternative programs throughout a variety of industries.

Different Types of Epoxy

There are several different types of epoxy out there out there, Every with its individual special Attributes and apps. A person frequent variety of epoxy is called "epoxy resin," which happens to be a clear liquid that could be blended with numerous additives to make personalized formulations. Epoxy resin is usually used for casting and encapsulating programs, like generating attractive items or encapsulating electronic elements.

Guidelines for Dealing with Epoxy

Working with epoxy involves cautious focus to depth and right system to ensure effective final results. One particular significant idea for dealing with epoxy should be to diligently Adhere to the company's Guidance for mixing the resin and hardener. Suitable mixing is important for acquiring the specified Houses with the epoxy and guaranteeing a powerful bond.

Security Precautions when Using Epoxy

While epoxy offers lots of Gains for several apps, it is necessary to get correct safety safety measures when working with this material. A person significant security precaution when utilizing epoxy is to operate within a nicely-ventilated space to stop inhaling fumes from your resin and hardener. Epoxy fumes can be annoying towards the respiratory procedure and will cause dizziness or nausea if inhaled in substantial concentrations.

Environmental Influence of Epoxy

Though epoxy gives lots of Positive aspects for various programs, it is important to look at its environmental effect. A person prospective environmental worry with epoxy is its production approach, which can include the usage of substances that can be hazardous into the atmosphere Otherwise thoroughly managed. It's important for makers to choose correct measures to reduce the environmental affect of manufacturing epoxy through responsible sourcing of raw components and waste management techniques.

Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Anthony Michael Hall Then & Now!

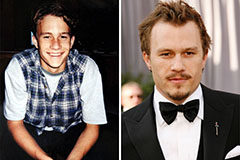

Anthony Michael Hall Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now!